Mon – Fri: 08:00 – 16:00

Sat & Sun: 09:00 – 16:00

70 Camberwell Church Street, London, SE5 8QZ

We’re right in the heart of Camberwell, 2 minutes walk from Camberwell Green. Closest stations are Denmark Hill (10 minutes walk, 5 minutes by bus) and Peckham Rye (10 minutes by bus) and you’ll see us out the window of any of the buses that stop at St Giles Church (12, 36, 171, 345, 436)

Please email any queries:

[email protected]

Phone: 0207 207 9567 (please try email first)

Lumberjack is your local general store, kitchen and artisanal deli, with an emphasis on speciality coffee, fresh bread, pastry & cakes, plus a carefully curated selection of local and continental food and drink.

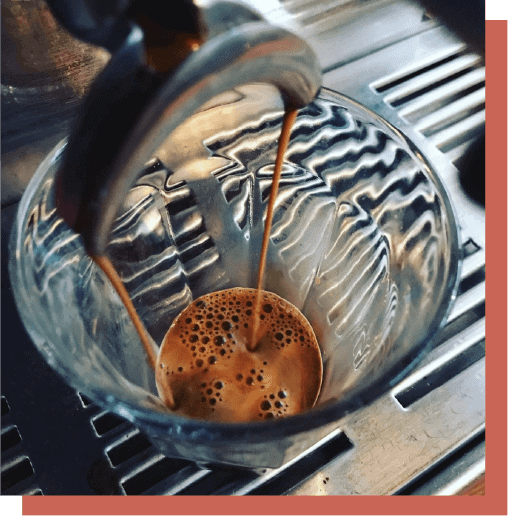

At our core, we are a speciality coffee shop, but we are proud to work with an amazing array of different suppliers and celebrate all forms of local craft produce - showcasing the best of what London has to offer, and beyond. We make sure to provide a range of options to suit various dietary requirements or tastes, including the goods on our shelves and our freshly made takeaway lunches behind the counter.

We are fully stocked each day with incredible sourdough bread, fresh pastry, cakes, meats, cheeses and speciality drinks - as well as baking up some of our own sweet treats, lunches and more. Over the summer we’ll also be serving Hackney Gelato ice cream to keep you going through the hot days!

Lumberjack opened its doors in January 2016 and we have been serving Camberwell ever since. We are part of London Reclaimed, an employment charity who run paid traineeships for young people from South East London as a step up in to skill-specific work. Our passion lies with these trainees, our staff and our suppliers – and being at the heart of the Camberwell community.

Since the pandemic in 2020, we have had to evolve the way we work and serve, but ultimately our manifesto is the same: to proudly serve Camberwell with amazing coffee and a range of tasty food without pretention or exclusivity, whilst focusing on seasonality, quality and provenance of the goods we sell.

We serve single origin coffee every day from Assembly Coffee, an award winning roastery in Brixton. They focus on high quality, responsibly sourced small-batch coffees from around the world. They commit to financially and environmentally supporting their chosen producers and those affected in the coffee supply chain – and are certified 100% carbon neutral.

We rotate guest filter coffees, and stock various retail bags from some of our favourite British roasters, including Curve Coffee, Hasbean, Dark Arts, Caravan Coffee and Round Hill Roastery. You can also find plenty of home brewing equipment for sale on our shelves

We sell a range of dairy products : from fresh Northiam Dairy milk to salted whey butter, cheeses and yoghurts from Neal’s Yard Dairy.

Our fridge also boasts an exciting array of traditional Italian cheeses imported by Nanona (you have to try the burrata!), some incredible vegan cheese from Honestly Tasty, and jars of spicy marinated feta from Blackwoods.

Though much of our offering in the shop is vegetarian and vegan friendly, we also have some products for the carnivores – cured and cooking chorizos and Paleta ham, and tinned fish from Brindisa.

Step into our back room to be tempted by a feast of artisan chocolates and treats… there are single origin speciality chocolate bars from LAND, large and small bars of Tony’s Chocolonely, authentic gluten free Italian amaretti, boxes of assorted cannoli, and outstanding luxury biscuits from Percy’s Bakery and Great British Biscotti.

Showcasing local artists and makers work. Prints, greetings cards, crockery, candles, facemasks and tea towels are among the beautiful items we have on offer. Our good friends at Goldfinch furniture have also hand crafted some stunning wooden chopping/serving boards to offer you.

Discover our range of artisanal dry store goods including spreads, flours, pasta, pulses sauces, olive oils and vinegars – we do our best to support local producers; including Rubies in the Rubble, who started in Borough Market, London Honey Co. and England Preserves.

We also stock specially imported Spanish goods from Brindisa, Italian goods from Nanona, award winning pesto, mustards, chutneys and preserves, and outstanding eggs from Rookery Farm. We do our best to supply items for our gluten free and vegan regulars, too, including various alternative milks and flours.

In addition to our tea, coffee and chai offering behind the counter, we are very proud to stock a special range of craft beers and ciders in our fridges, and natural wines, craft spirits, and soft options too. In South East London, we are lucky to be surrounded by some amazing craft breweries, and we have selected a range from some of them including Peckham’s own Brick Brewery, Kernel, Villages, Pressure Drop, and Boxcar, alongside some exquisite keeved ciders and perries from Oliver’s, Pilton and Little Pomona.

Guided by our friends at Les Caves de Pyrène, we have selected a range of wine, red, pink and bubbly wines for your perusal, with a focus on promoting natural, vegan and biodynamic wines – those that are expressive of their homeland, made by hand with minimal chemical intervention and where the winemaking shows maximum respect for the environment.

For something a little harder or fruitier, we stock East London Liquor’s gin, rum and premixed cans, as well as LuvJus’ craft pop – a new local start up who give a portion of their proceeds to LGBTQ+ charities and initiatives.

This site uses cookies.

Find out more on how we use cookies.